Assistive Technology for Hands-Free Teeth Brushing

People with high-level spinal cord injuries are unable to maneuver a toothbrush and must rely on caregivers to brush their teeth for them. For my senior design project, I went through a process of ethnography to explore user needs, ideated potential solutions, created rapid prototypes, performed hazard and risk analysis, iteratively designed and fabricated a functional prototype, and tested the device.

Background

Every year, over 6,000 people in North America get cervical spinal cord injuries, which often results in partial or complete paralysis of the legs, trunk, arms, and hands. Many of these people cannot use their hands to brush their teeth and require a caregiver to brush their teeth for them. However, caregiver assistance is often ineffective and unreliable, and thus many people with cervical spinal cord injuries have poor oral hygiene which results in dental decay and periodontal disease, and increased risk of cardiovascular disease. It is also uncomfortable and invasive to have someone else brush your teeth, and the need for assistance damages people’s sense of dignity.

Project Lead

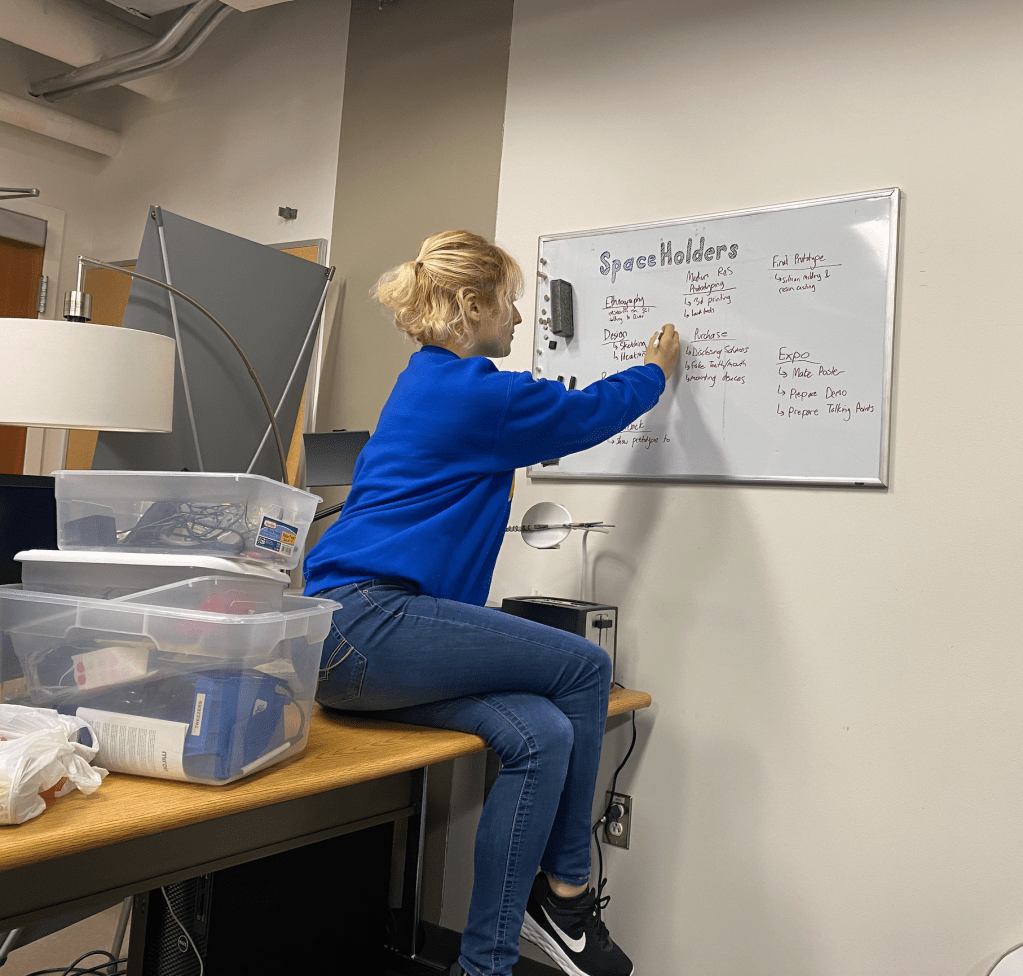

As Project Lead, I managed our design team to set up meetings, plan weekly timelines, follow up regarding deliverables, and review/revise documents to ensure quality. I also developed agendas, finalized meeting minutes, and served as the primary point-of-contact with our course instructor.

Ethnography: Exploring User Needs

Spinal Cord Injury Unit at UPMC Mercy

Talked with spinal cord injury patients, and physical therapists, occupational therapists about discomfort, dependence, and unreliability associated with caregiver teeth brushing.

Center for Patients with Special Needs at Pitt Dental Clinic

Talked with a special needs dentist about difficulties of dental care for spinal cord injury patients, as well as difficulties of caregiver teeth brushing.

Dr. Komoroski's Orthodontist Practice

Talked with orthodontist who treats some patients with impaired mobility, and discussed needs of different patient populations.

Identifying Existing Solutions

Found that nothing is available for teeth brushing that is truly hands-free.

Background Research

Explored the varying degrees of function for different spinal cord injury levels and identified target user of C4-C6 spinal cord injury.

Literature Search

Found prior research on oral health of spinal cord injury patients and efficacy of caregiver brushing.

Ideation

I lead my group through multiple rounds of timed silent sticky note ideation so we could generate as many ideas possible. All ideas were shared out loud afterwards such that all ideas were considered by the team.

We grouped similar ideas together and voted on our top ideas so we could try to rapid prototype them.

Rapid Prototyping

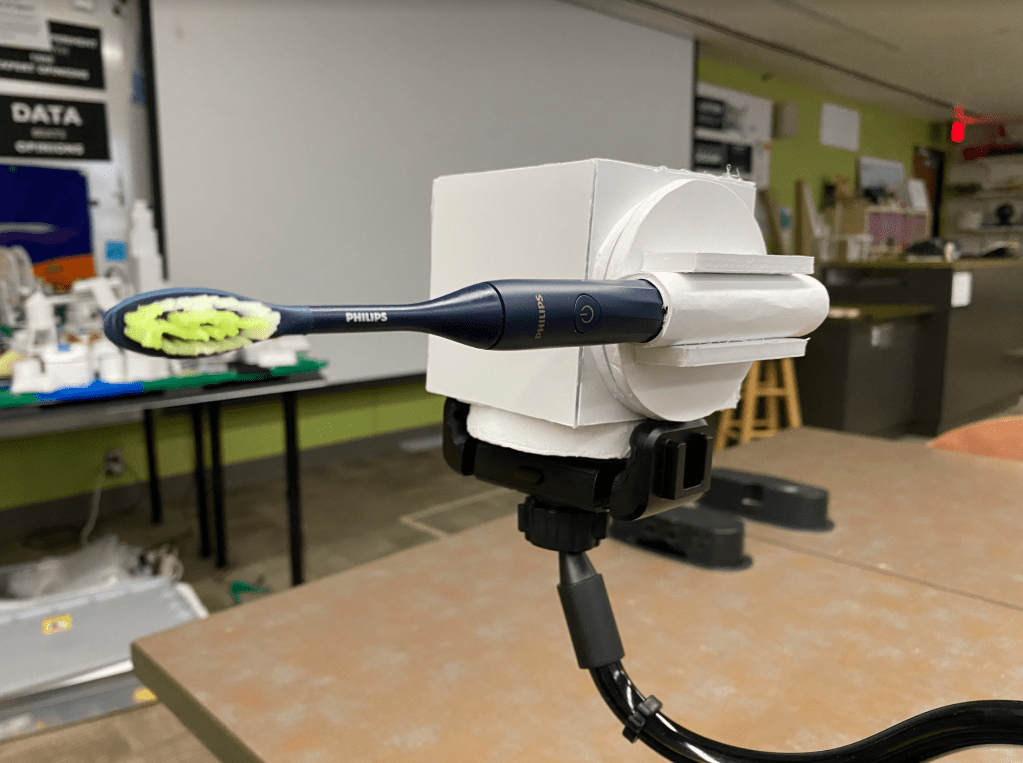

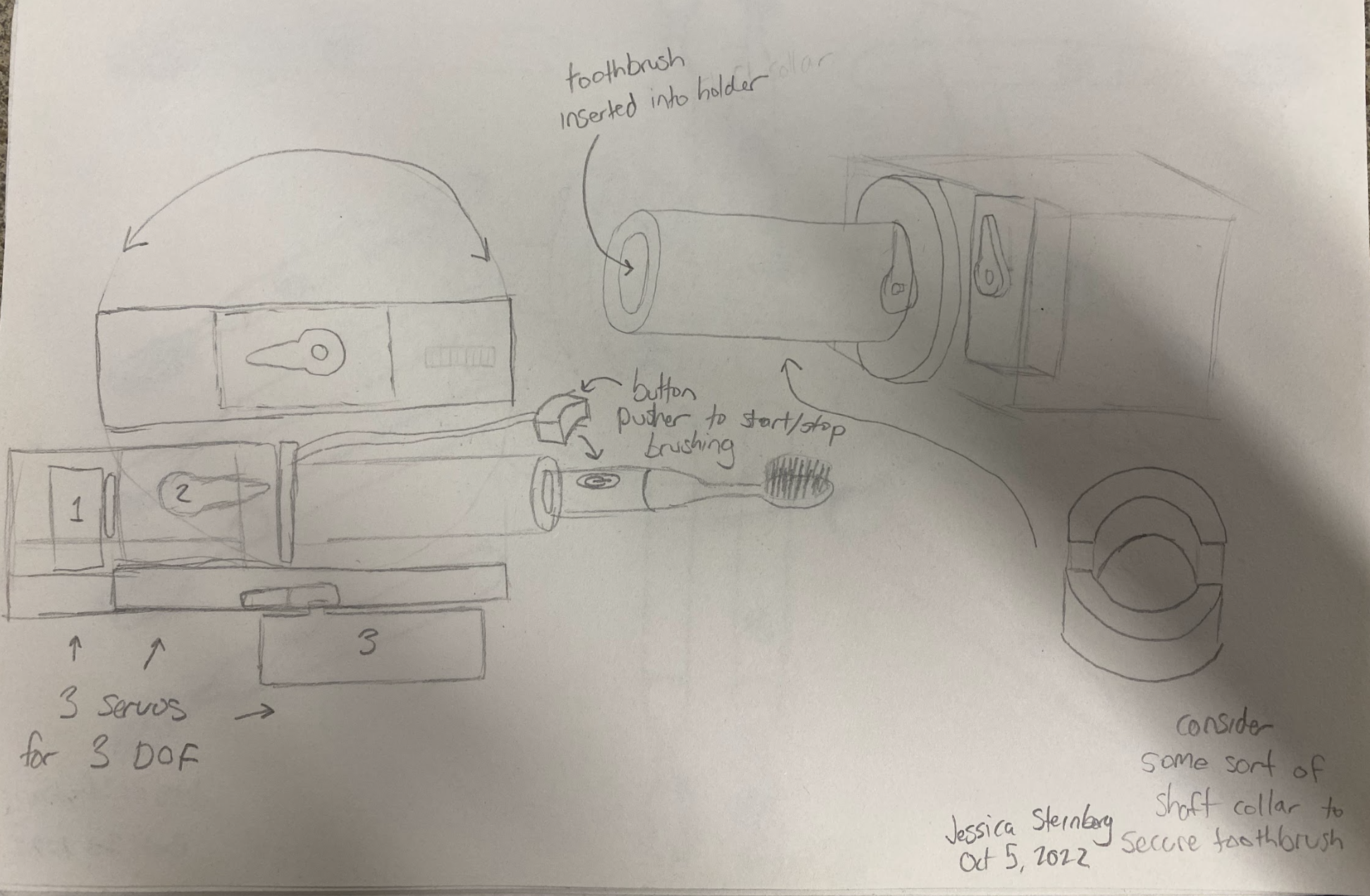

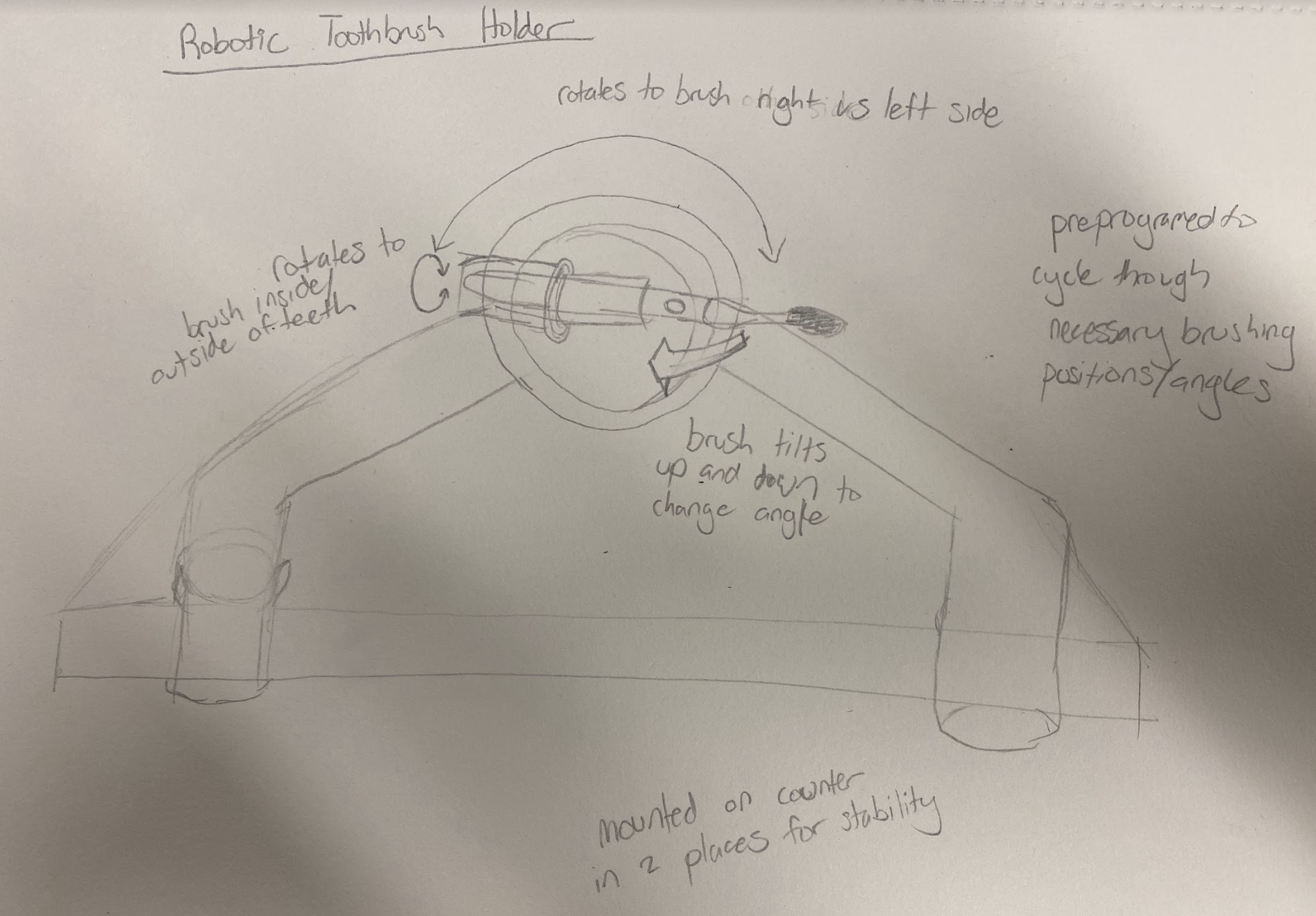

My idea from the ideation session was to make a robotic toothbrush holder that would move the toothbrush around so the user doesn’t need their hands to do it.

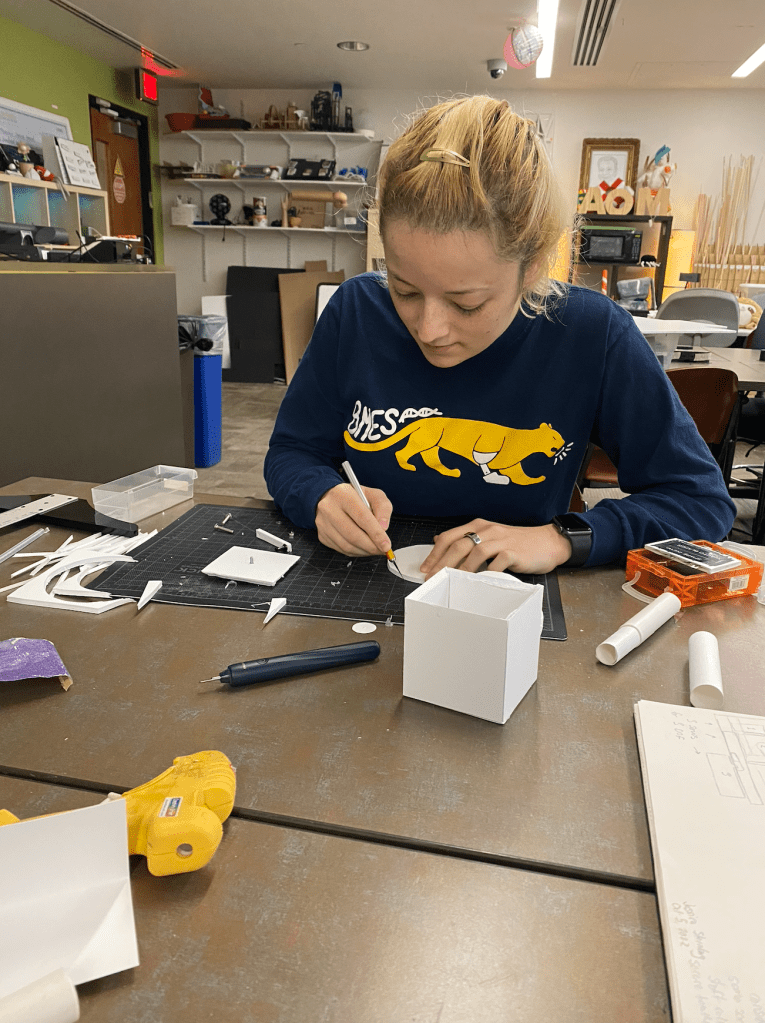

I made a low-resolution prototype using foam core and some nuts and bolts to act as an axes and allow pieces to move.

I went with my teammates back to our ethnographic sites to show my rapid prototype along with my team members’ prototypes to patients and clinicians. When comparing the prototypes, everyone we talked to preferred the robotic toothbrush holder idea.

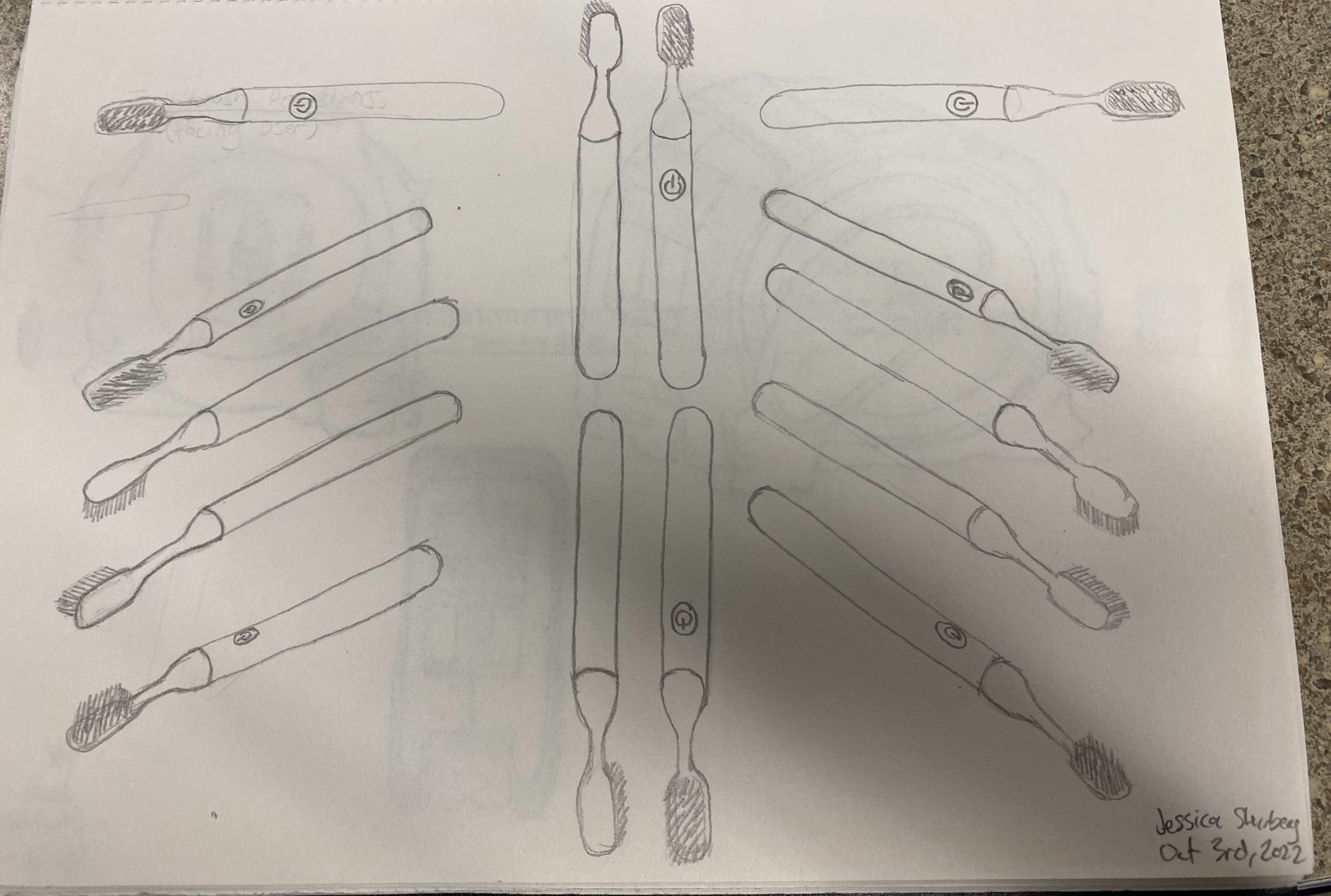

Sketching

HAZARD AND RISK ANALYSIS

We used various tools to perform a hazard and risk analysis, and determined that the biggest risk was that the device might injure the user's mouth or head when moving. To mitigate this risk, we agreed that the final prototype would need to have a buzzer and light to alert the user before each movement of the toothbrush.

MINIMUM VIABLE FEATURE SET

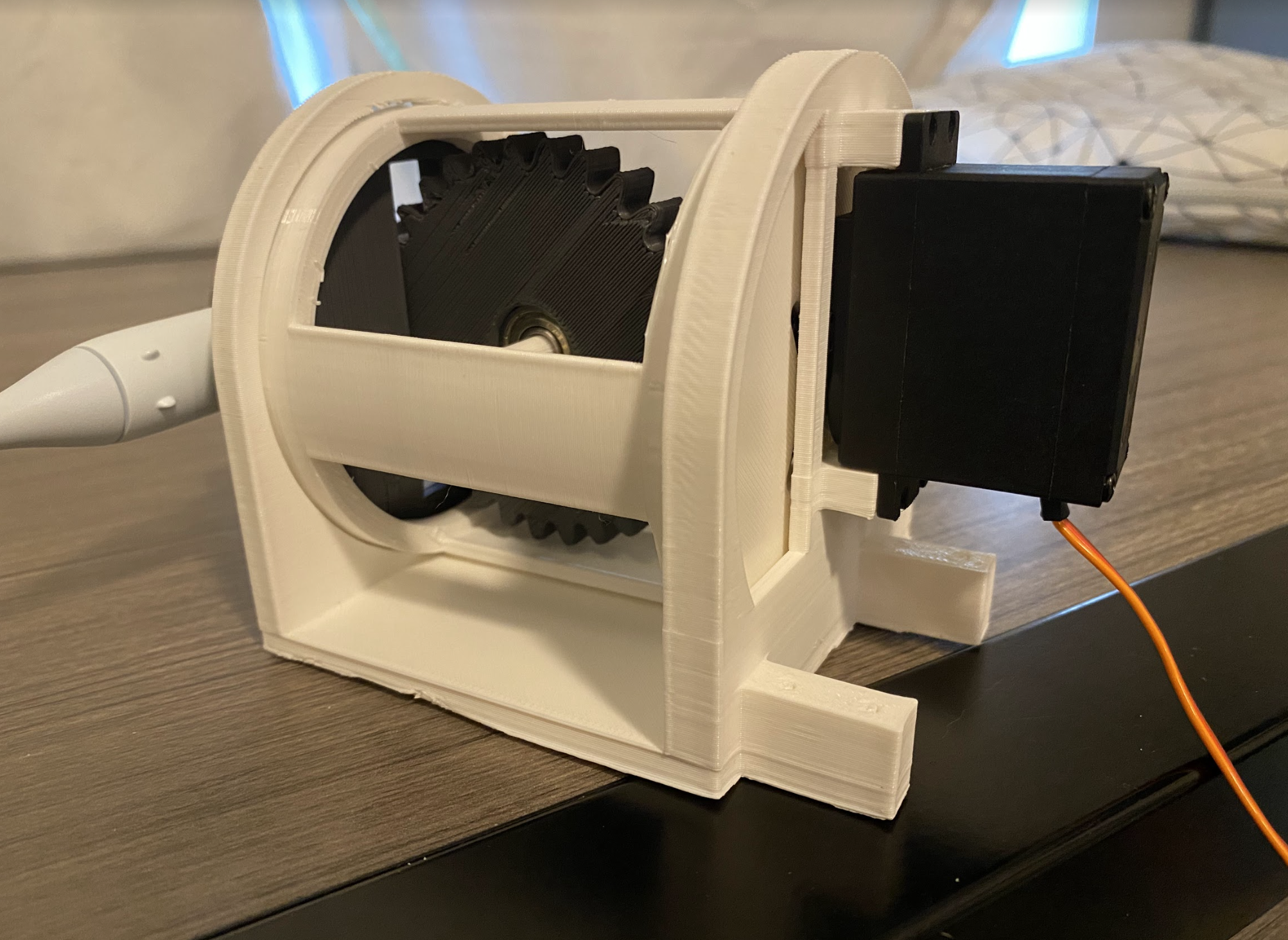

From the user needs and risk analysis, we formed our minimum viable feature set to guide prototyping efforts for senior design. Features included the need for toothbursh movement onat least 3 axes, compatibility to be controlled with an 3.5 mm external assistive tech switch, the ability to be mounted using any 1/4 20" camera mount, incorporation of a audio and light warning before the toothbrush moves, and the ability to remain rigid in each configuration against the external force applied by the user's teeth on the device.

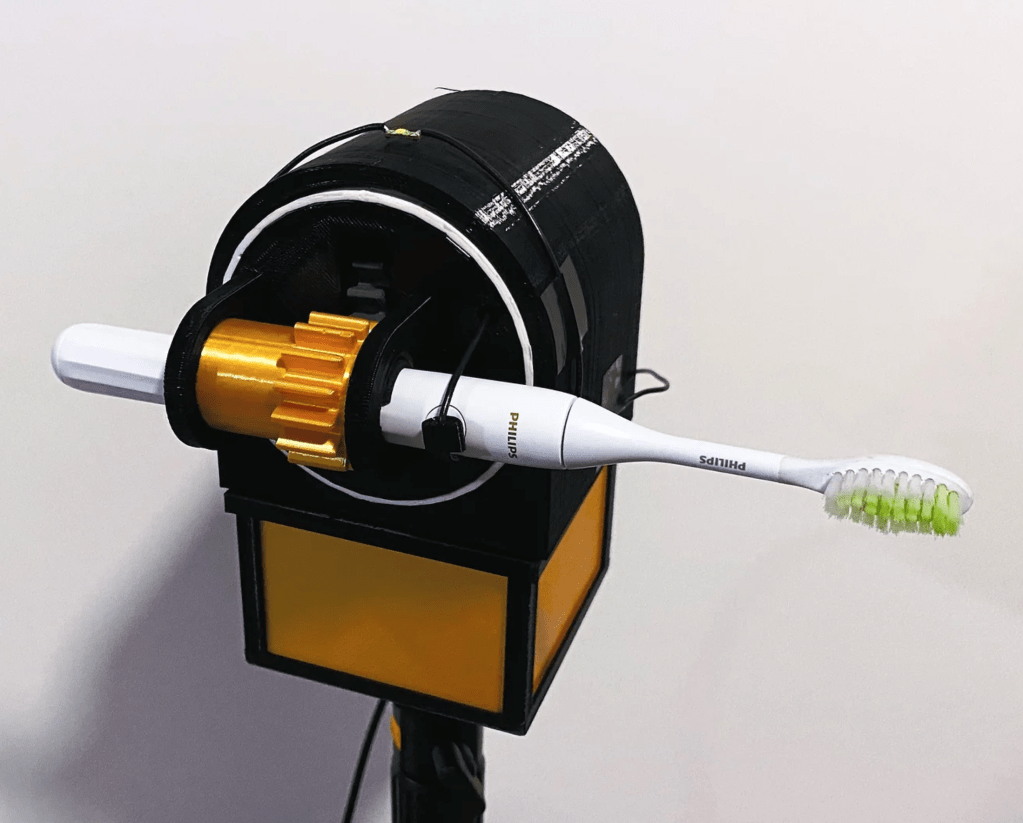

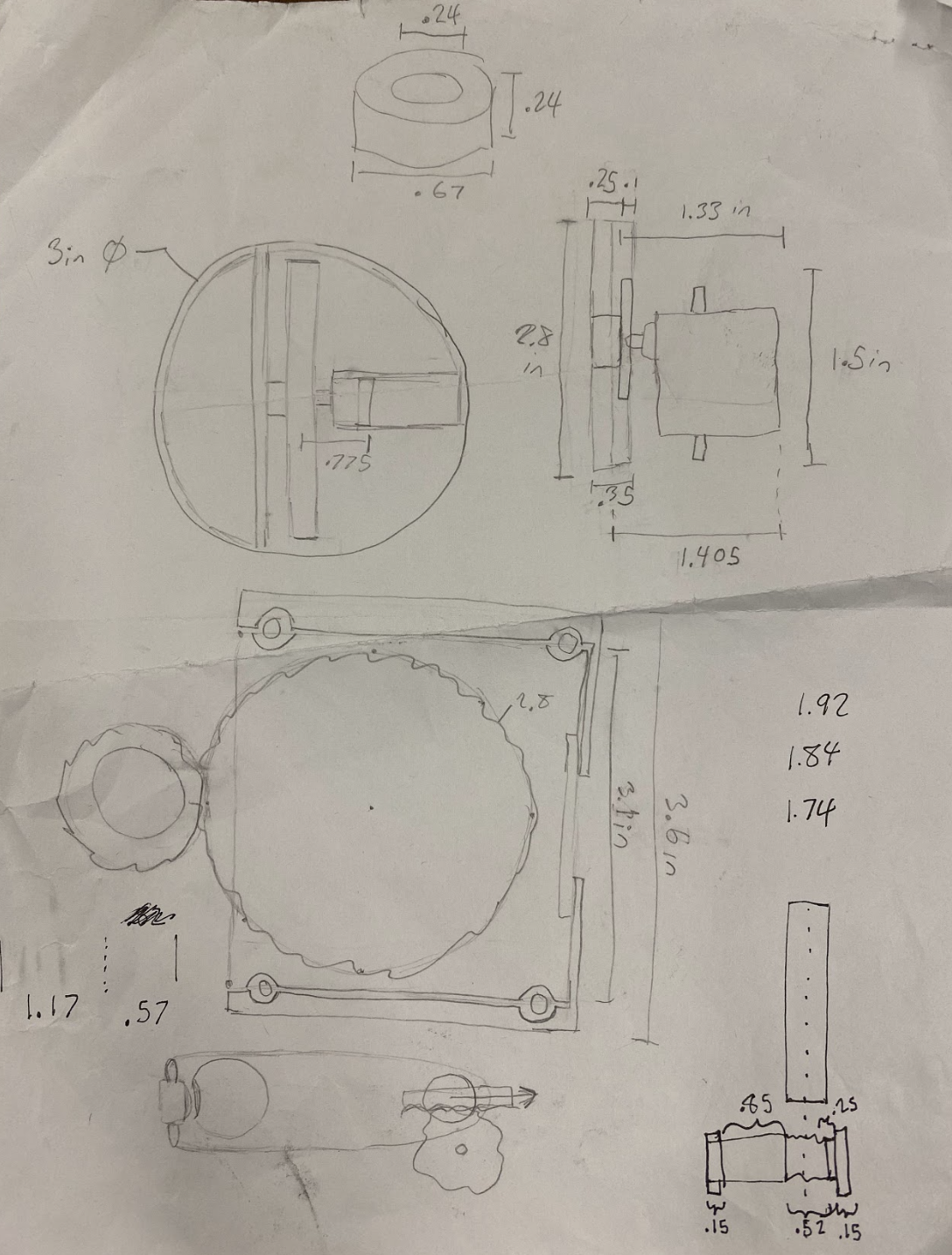

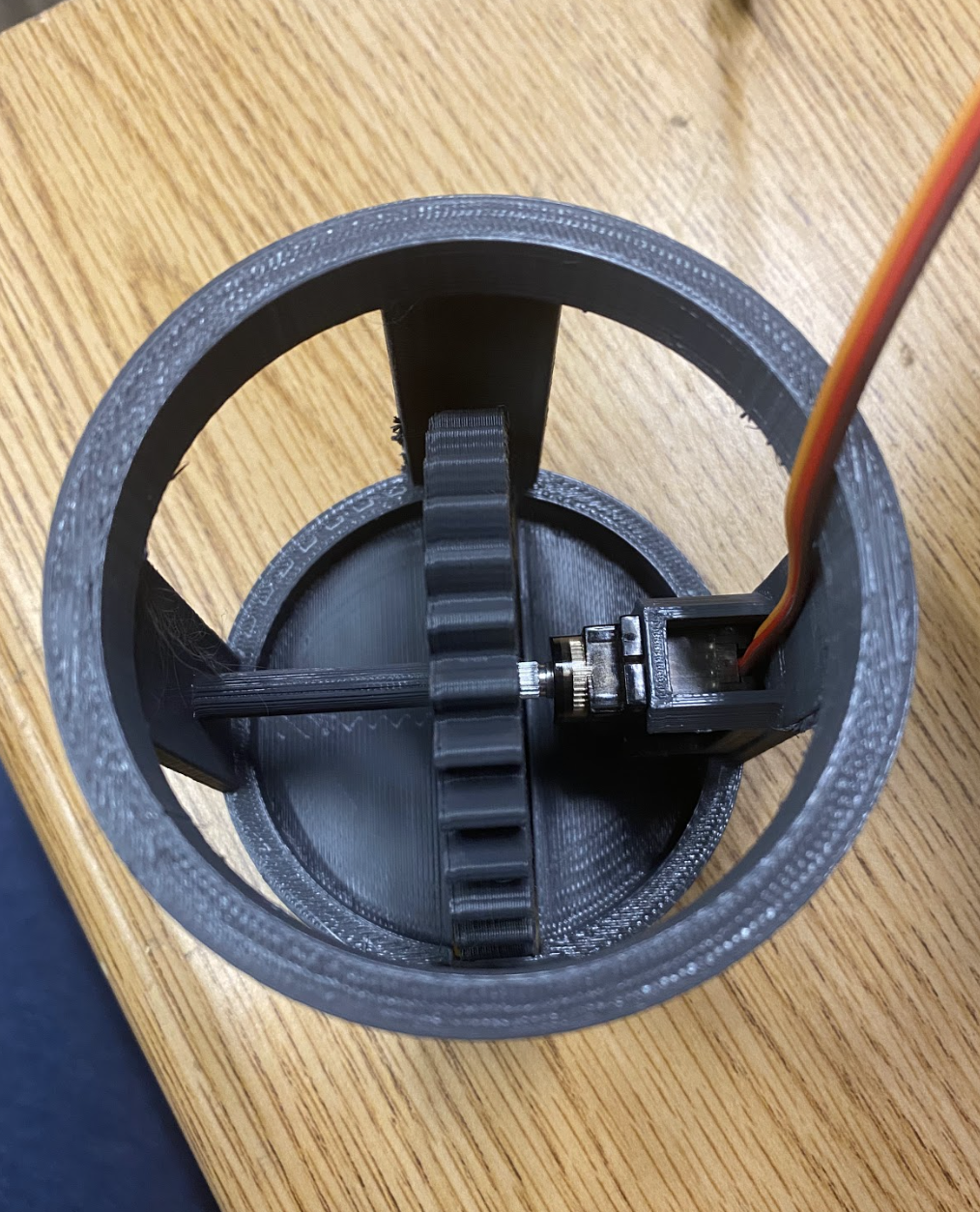

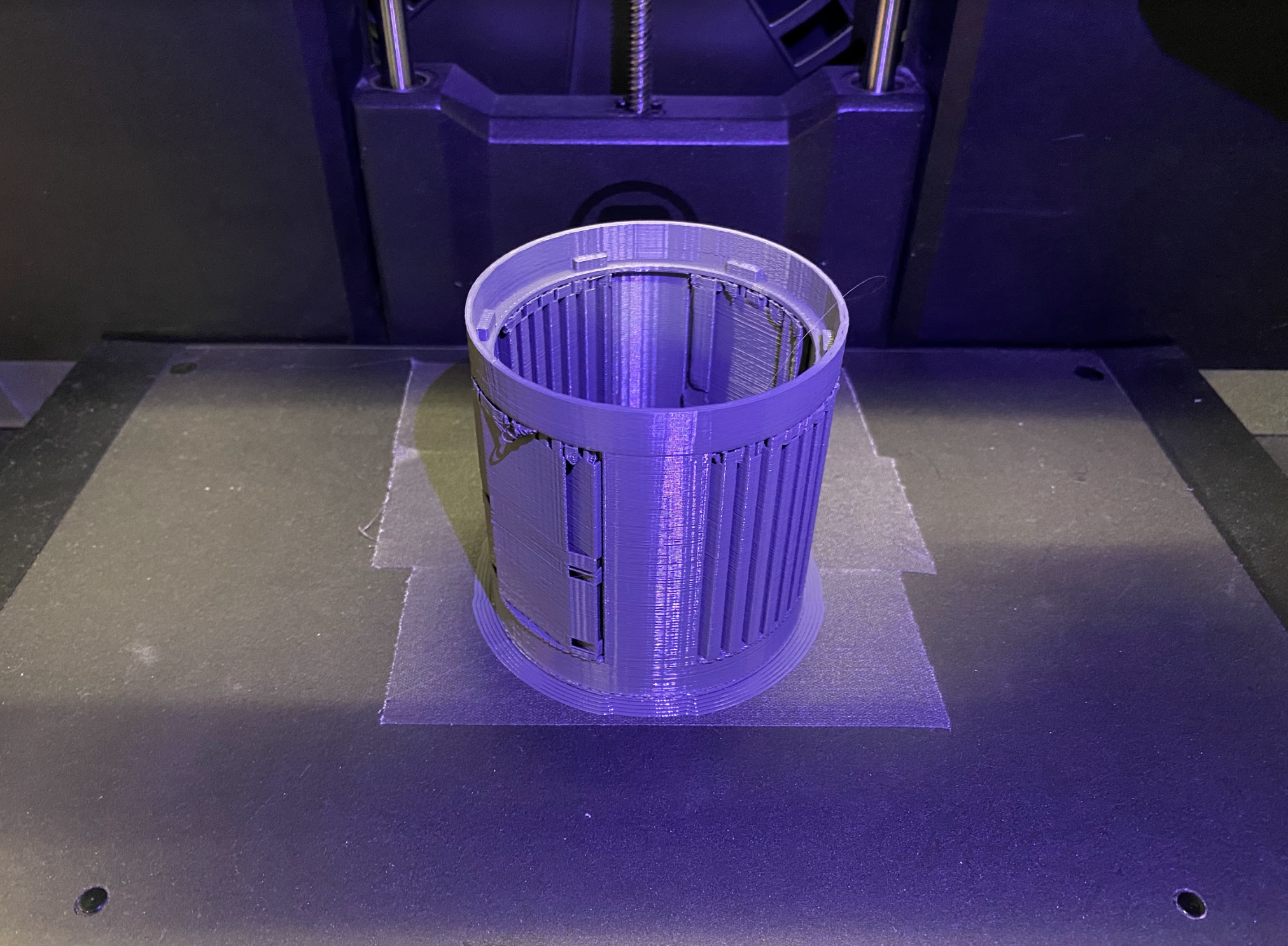

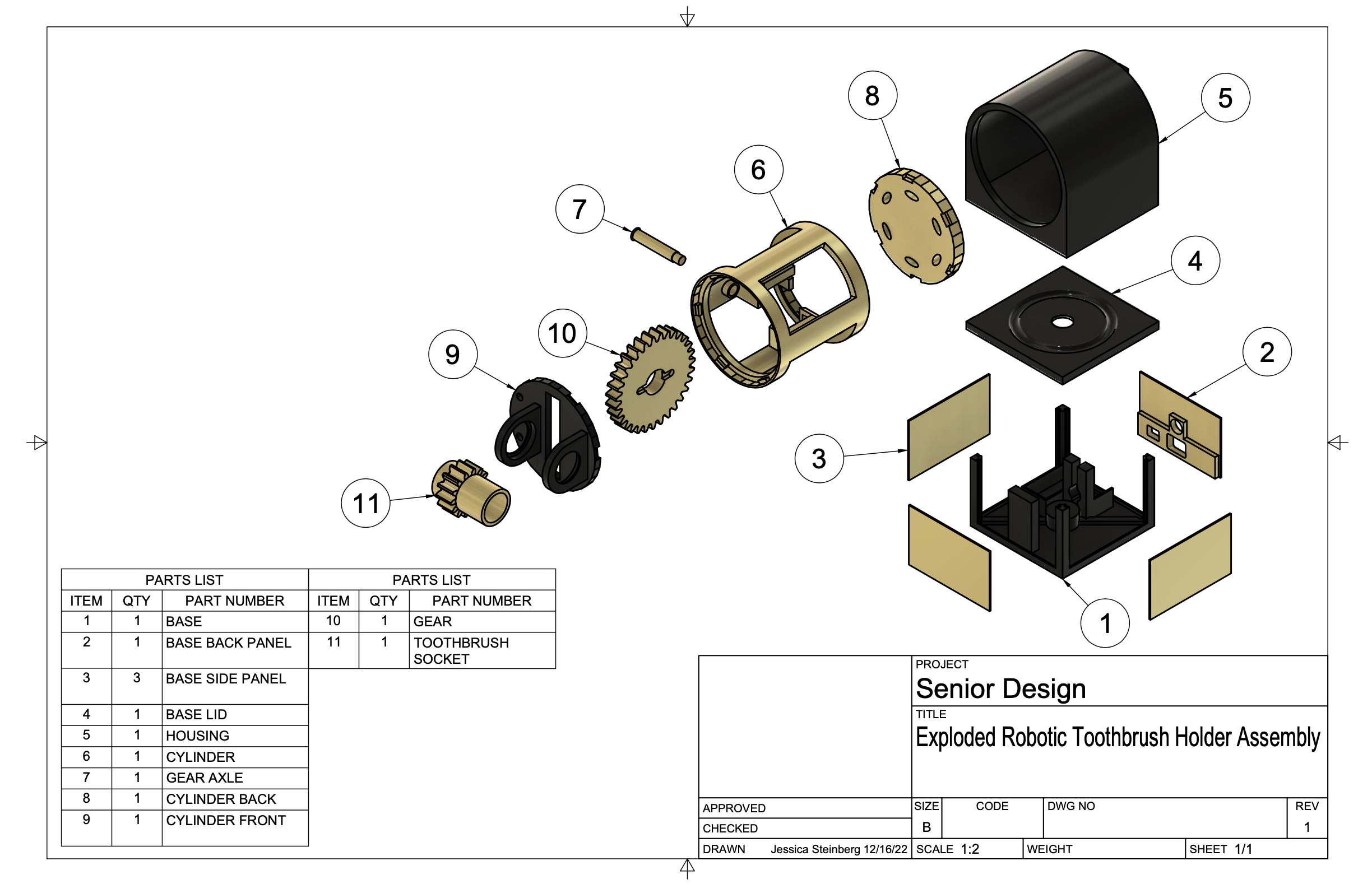

CAD AND 3D PRINTING

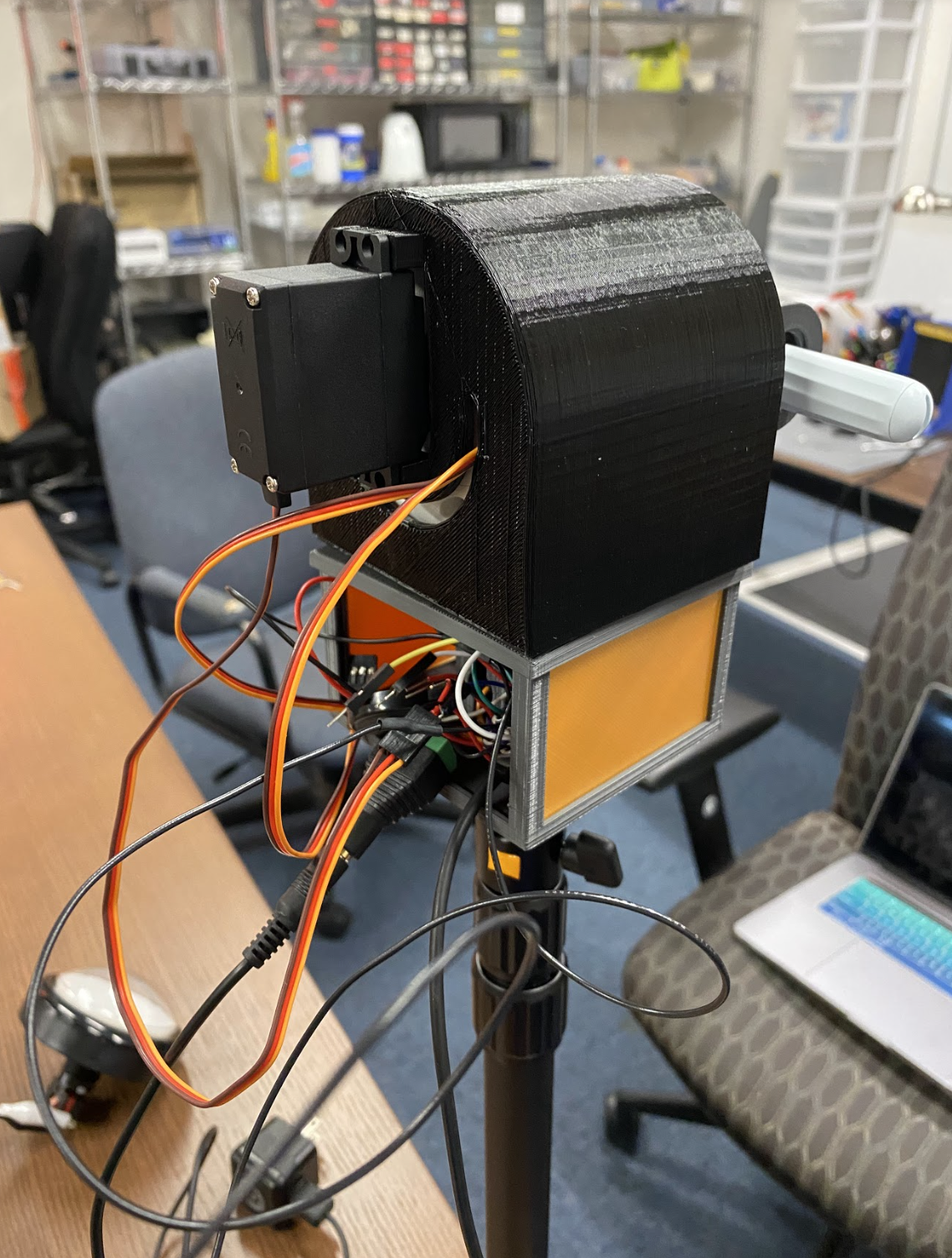

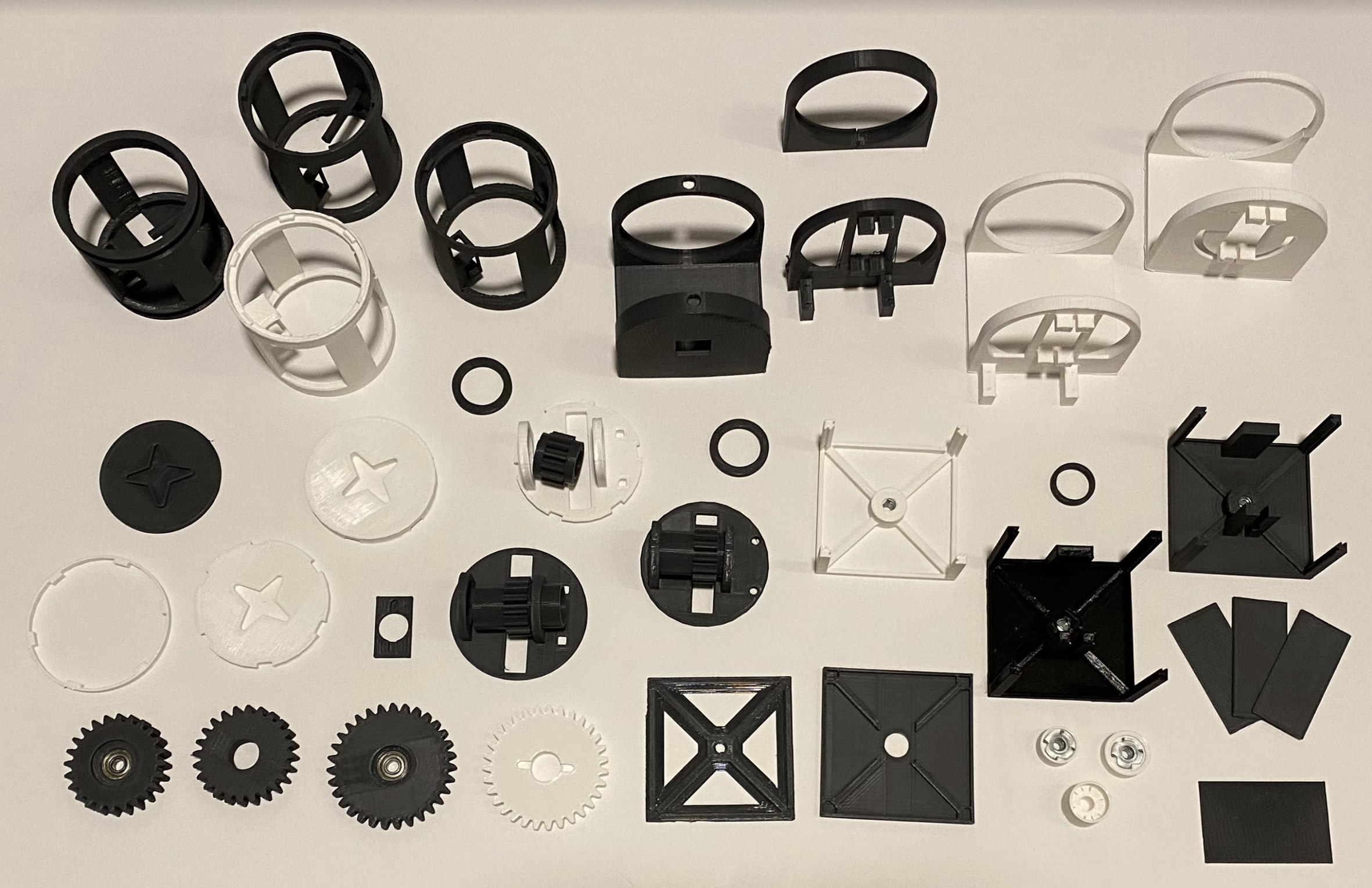

My primary contribution to our senior design project was designing and developing the prototype. While I consulted my teammates for ideas on features and troubleshooting, all of the images below show my own work on the prototype.

I designed all of the parts in Fusion 360 and iteratively 3D printed, tested, and redesigned the parts to improve functionality and resolve tolerance issues.

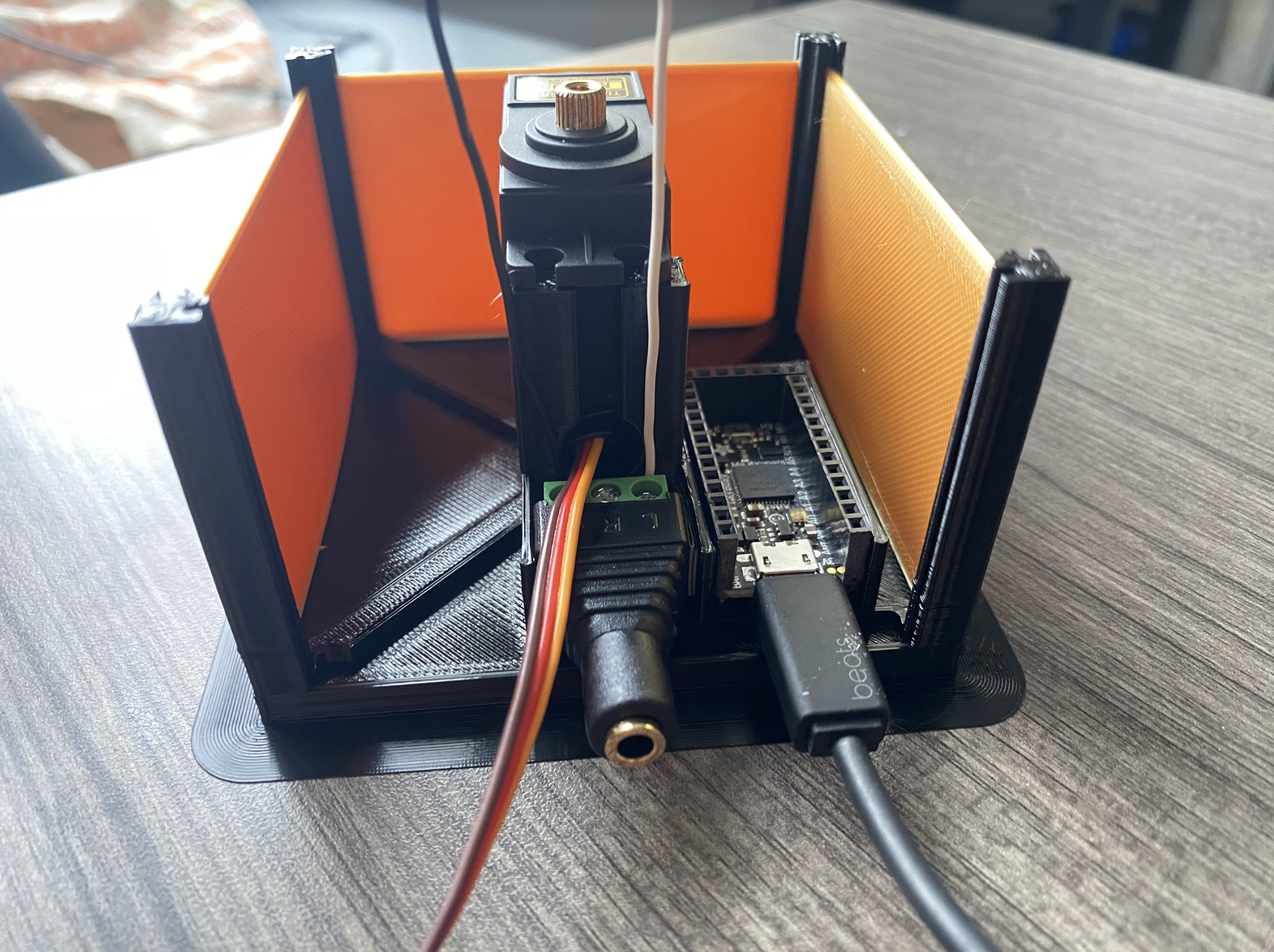

Electronics

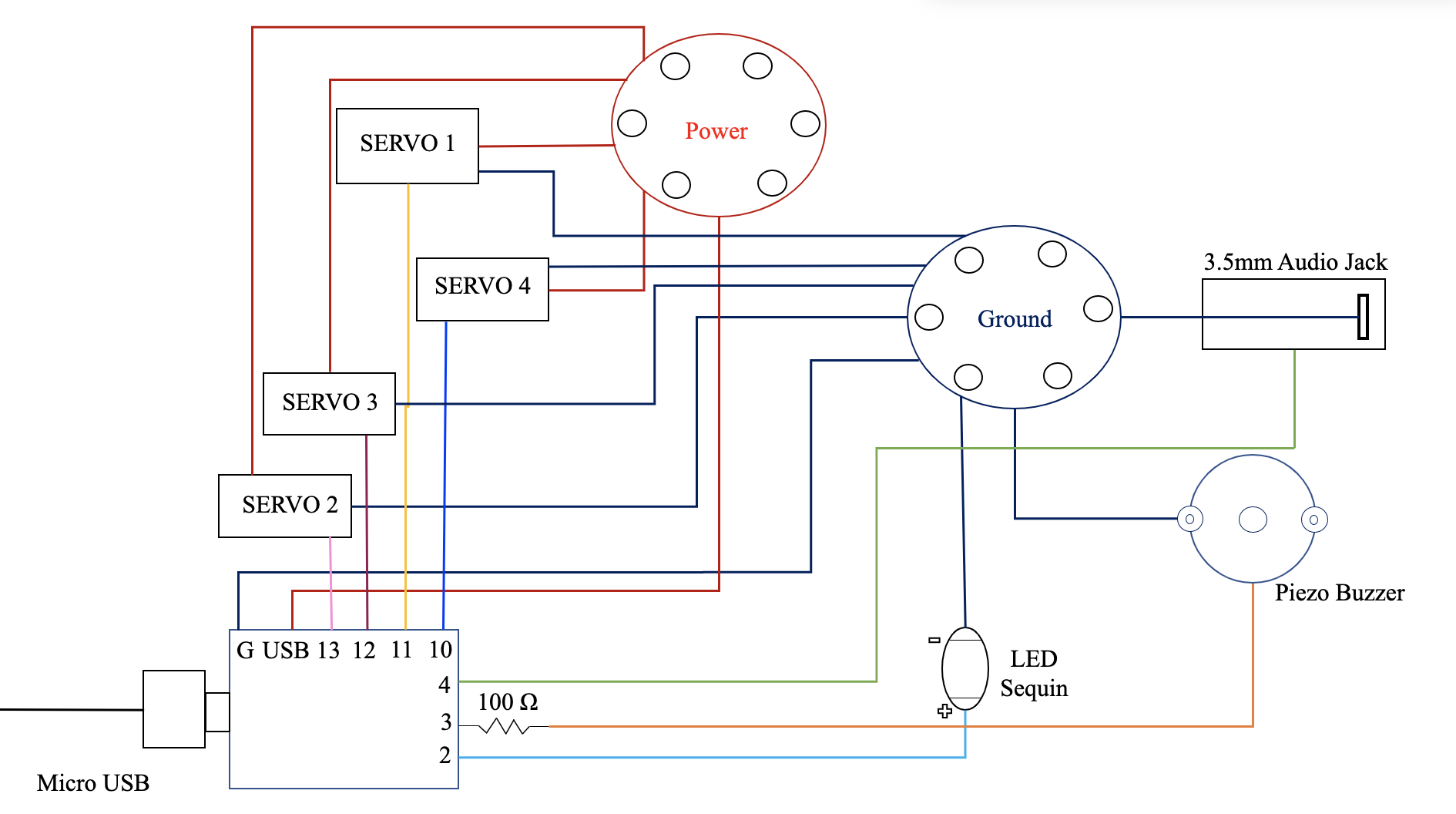

I tinkered with an Arduino UNO and a breadboard to experiment with controlling servo motors to make the device move.

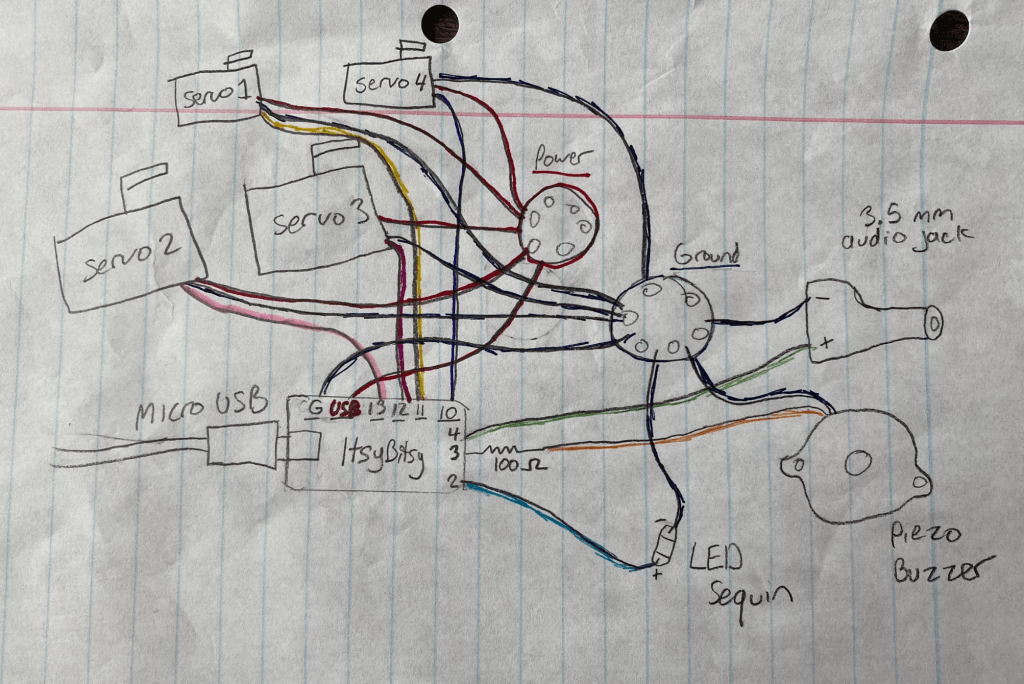

I mapped out all the components of the electronics system, including four servos, an LED. a piezo buzzer, a 3.5 mm audio jack for the external switch, a mircrocontroller, and a power supply.

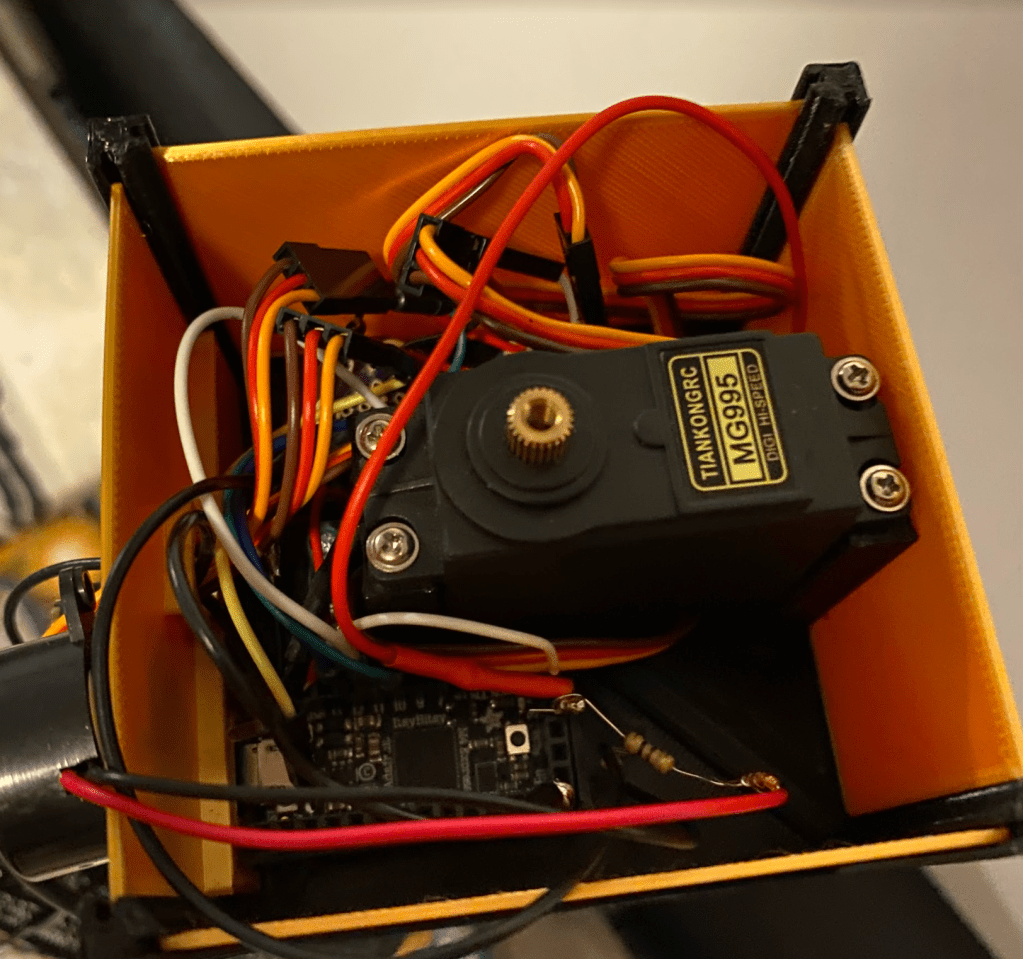

I switched from using the Arduino Uno to an Adafruit ItsyBitsy M4 Express microcontroller to reduce the side of the electronics and allow all the components to fit in the base enclosure of the device.

I was sucessfully able to get all of the electronic components to fit in the base enclosure.

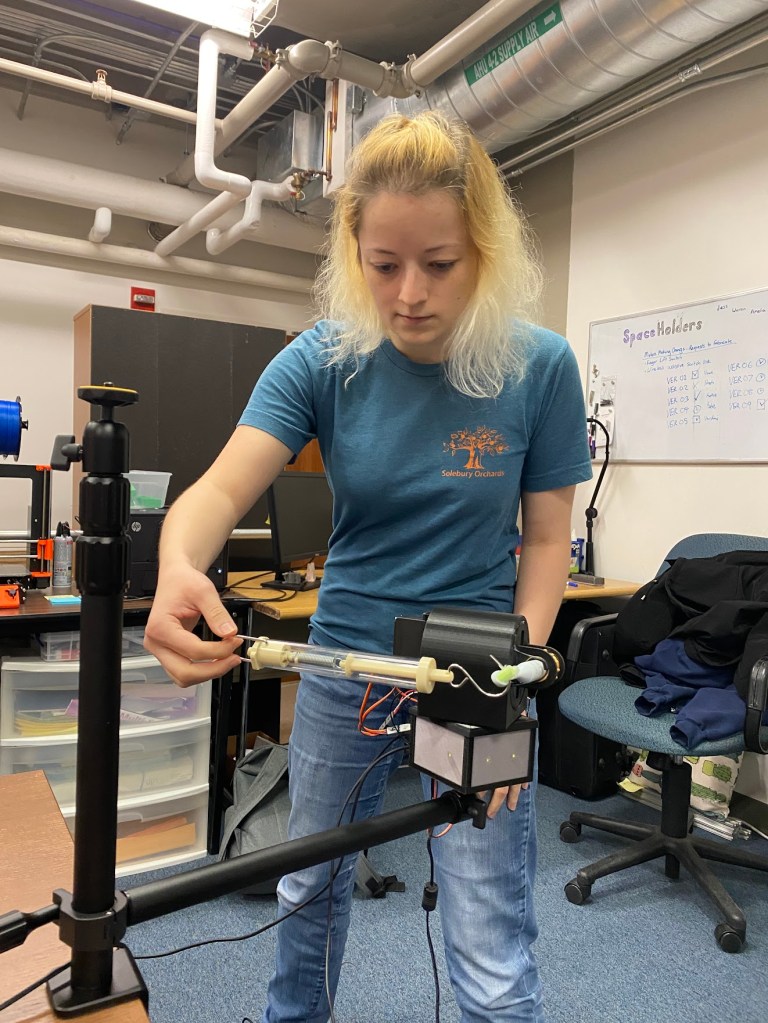

Final Prototype

Verification Testing

My team performed a number of different verification and validation tests to confirm that our device meets the specified design requirements and the user needs. I was responsible for designing and conducting two of our verification tests.

My first verification test was designed to test whether the device could resist the applied force of someone brushing their teeth. Since the recommended applied force for teeth brushing is 0.2-0.4 lbs, I set the acceptance criteria as the device remaining rigid against 1 lb of applied force.

I measured the applied force using a spring scale for three trials on both the right and left side. The device successfully resisted 1 lbs of force for all three trials on both sides.

My second verification test was designed to test whether the device rotates to all of the correct specified angles throughout the sequence. I set the acceptance criteria as the device rotating to +/- 3 degrees of the correct angle for all positions throughout the teeth brushing sequence.

To measure the angles, I attached zip ties to various components of the deivde which created reference lines for me to measure the angle between. Then I measured the angle by taking pictures of the device at the different positions and measuring the angles of the pictures my computer screen using a protractor.

The device rotated to +/- 3 degrees of the specified angles for all positions except one, where the device reached 170 degrees instead of the specified 180 degrees.

While some of our verification tests passed and other tests failed, it is important to notes that all the results are questionable since we performed the tests with a low sample size and used a design prototype rather than a production equivalent product.

Project Video

I created this video to document my team’s design process.

Feel free to give it a watch to see the Robotic Toothbrush Holder in action!

Design Expo

I presented our final prototype with my team members at the Swanson School of Engineering Design Expo at the end of both the fall and spring semesters.

You must be logged in to post a comment.